The automotive industry is undergoing a seismic shift. Electric Vehicles (EVs) are rapidly gaining traction, and with them, a growing demand for specialized motors. Within this landscape, accurately differentiating between gear motors and regular motors is crucial for automotive parts enterprises. Misidentification can lead to significant operational inefficiencies, incorrect component selection, and ultimately, compromised vehicle performance and safety. This article explores common mistakes made when distinguishing between these motor types and provides actionable solutions to ensure accuracy and optimize your business operations. We’ll also touch upon how advancements in AI are impacting motor design and selection.

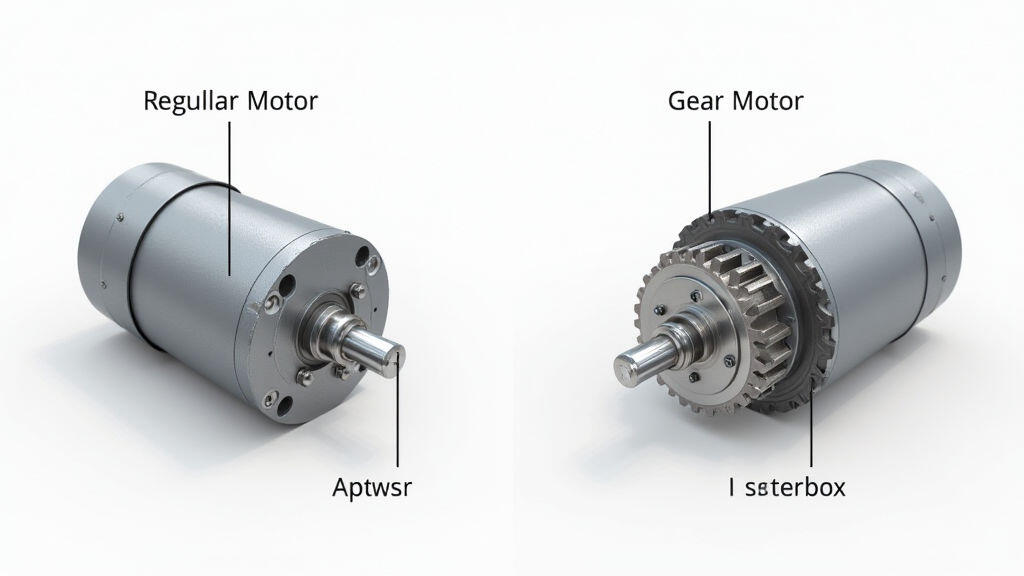

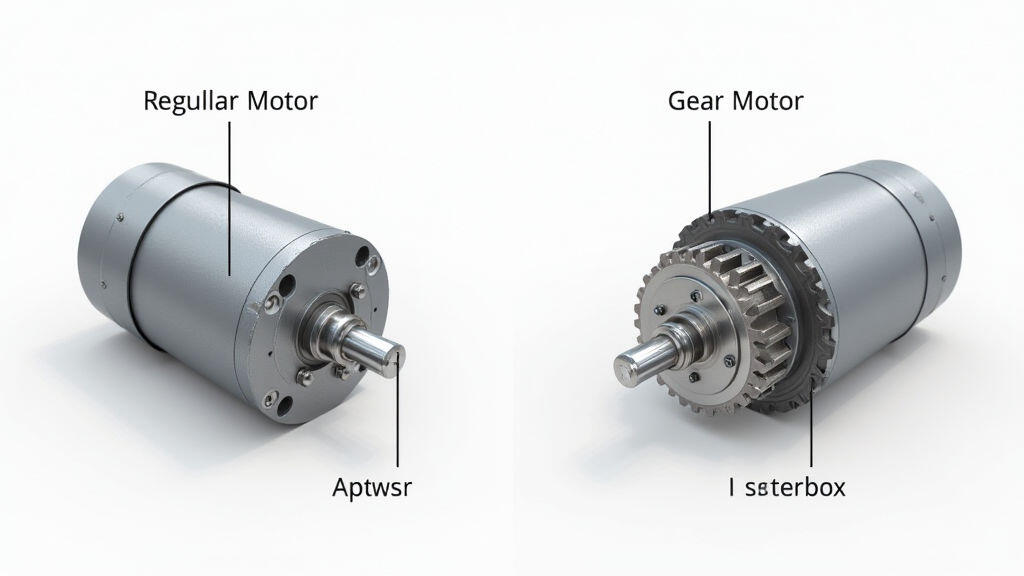

At its heart, the distinction between a gear motor and a regular (often referred to as direct drive) motor lies in the presence of a gear system. A regular motor provides rotational force directly to the output shaft. A gear motor, on the other hand, incorporates gears to modify the motor's torque and speed. This allows gear motors to deliver higher torque at lower speeds compared to regular motors of similar size. This is a fundamental difference with significant implications for automotive applications.

The benefits of using a gear motor include:

Several common pitfalls can occur when differentiating between gear motors and regular motors, leading to costly errors.

1. Sole Reliance on Motor Size: Often, businesses mistakenly assume that a larger motor is always a gear motor. While gear motors can be larger, they are not inherently so. Regular motors come in a wide range of sizes, and larger motors don’t automatically indicate the presence of a gearbox.

2. Confusing Motor Types Based on Visual Appearance: While some gear motors are visually distinct due to the gearbox casing, not all are. Some gear motors have integrated gear housings that are seamlessly incorporated into the motor assembly, making them difficult to identify visually.

3. Neglecting Torque and Speed Requirements: Failing to carefully analyze the torque and speed requirements of the target automotive application is a major error. A regular motor might be suitable for certain tasks but will likely underperform in applications demanding high torque at low speed.

4. Ignoring Gear Ratio and Efficiency: Gear motors have a gear ratio that significantly impacts output speed and torque. Ignoring this ratio during selection can lead to suboptimal performance. Furthermore, gearboxes introduce energy losses. Failing to consider the overall efficiency of the gearmotor can impact vehicle fuel economy.

The rise of AI and IoT (Internet of Things) is revolutionizing motor selection and identification.

MES-Drive understands the complexities of the automotive parts industry. We offer a comprehensive range of gear motors and regular motors, backed by expert technical support to assist our clients in making the right choices. Our commitment to quality and innovation ensures that our products meet the stringent demands of modern automotive applications. MES-Drive provides detailed technical specifications and application guidance to ensure accuracy in motor selection and optimal performance. We also actively embrace and integrate AI-powered tools to enhance the motor selection process.

In conclusion, accurately differentiating between gear motors and regular motors is a critical skill for automotive parts enterprises. Avoiding common mistakes like focusing solely on size, misinterpreting visual cues, neglecting torque and speed requirements, and ignoring gear ratios can significantly improve operational efficiency, reduce costs, and enhance product quality. Embracing technology, especially AI-powered tools, offers a pathway to streamline the motor selection process and stay ahead of the evolving demands of the automotive industry.

With the continued growth of EVs and autonomous driving, the demand for high-performance, highly efficient motors will only increase. Enterprises that prioritize accurate motor selection and invest in technological solutions will be well-positioned to thrive in this dynamic and rapidly transforming market. The integration of AI in motor design and optimization is a key trend, promising even greater efficiency and performance in the years to come. MES-Drive is committed to staying at the forefront of this innovation, offering our clients the solutions they need to succeed in the evolving automotive landscape.

Leave A Reply

Your email address will not be published. Required fiels are marked